Silicon and Silver Recovery from end-of-life Solar Panels

Being one of the easiest green energy sources to transition into, solar energy is preferred globally over other alternatives like hydrothermal or nuclear energy. Solar technologies harvest the sun’s energy in three primary ways: Concentration of solar (CSP), solar heating and cooling (SHC), power, and photovoltaics. While solar-based temperature regulation has limited applications and CSPs are generally plants that concentrate the sun’s energy via mirrors to generate electricity using turbines or engines, photovoltaics, abbreviated as PV, directly generates electricity from sunlight via electronic processes and can replace the entire electricity grid for a single residence. Along with environmental and financial considerations, several economic incentives promoted solarization at several levels, ranging from tiny homes to massive governmental areas.

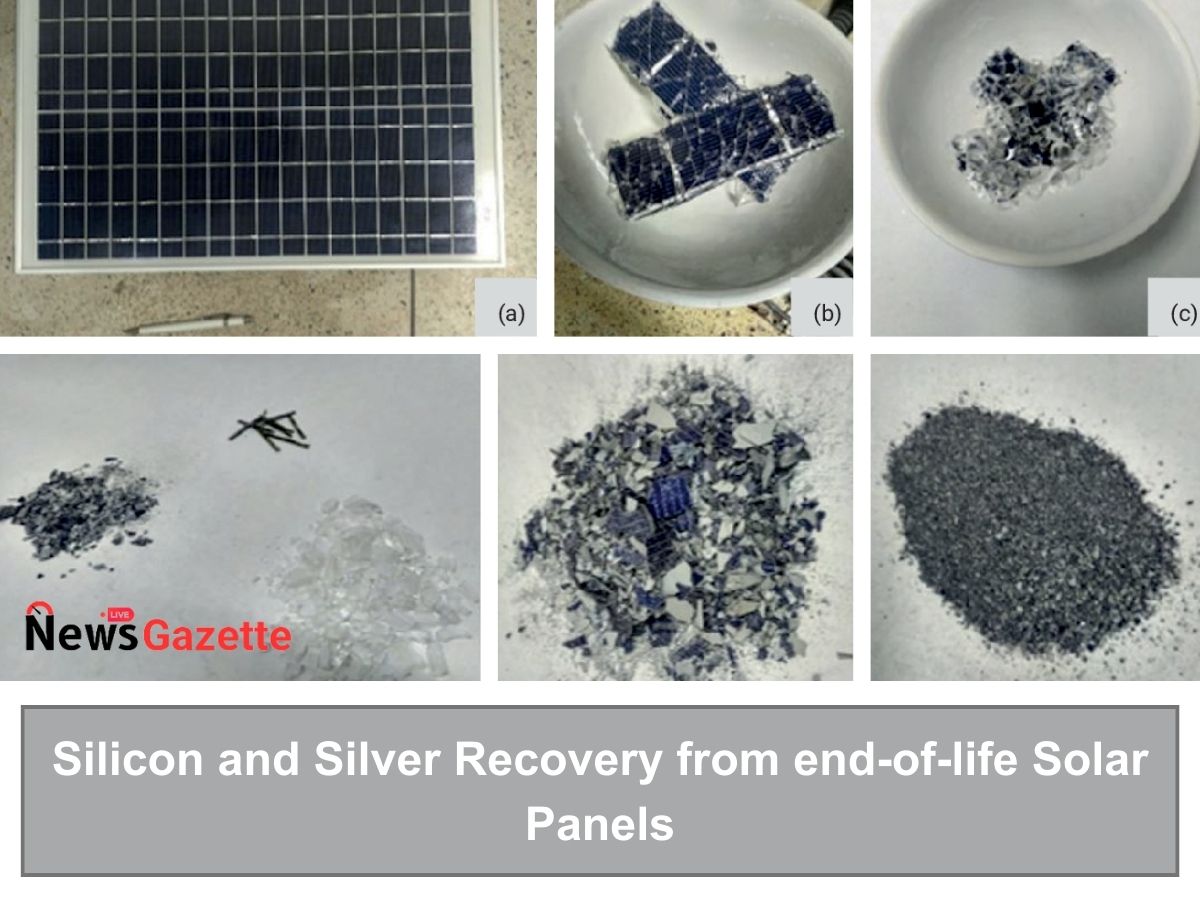

A sharp decline in panel costs due to newly emerging Chinese panel producers encouraged existing consumers to replace their panels with newer and better models. Hidden from the public conscience, this has led to a significant buildup of solar waste. While most considered it a hassle, the French Alternative Energies saw it as an opportunity for financial gain. Working in collaboration with the Atomic Energy Commission (CEA), they developed a recycling strategy for discarded PV cells wherein silicon and silver recoveries were achieved using supercritical CO2.

A post-pandemic commercial boom in the solar industry was experienced due to a 26% defray in solar-related expenses as a part of the Solar Investment Tax Credit. A 10% step down for commercial installers and complete eradication for homeowners is predicted after 2023. In addition, an average 1% decrease in panel efficiency every successive year has encouraged an avalanche of PV replacement, resulting in a collateral increase of PV waste. The International Renewable Energy Agency (IRENA) estimated the generation of approximately 78 million tons of solar waste by 2050. Given the predicted figures and substantial demand for raw materials, the CEA recycling strategy greatly benefits the solar industry.

“The CEA has been deploying R&D for more than 60 years in a circular economy context, with the nuclear fuel cycle which is part of this logic of circularity,” said Virginie Basini, the head of the department, CEA. Backed by CEA’s technical expertise and collaborative spirit, the recycling strategy developed was inspired by nuclear power waste treatment protocols. CEA’s method uses supercritical carbon dioxide (CO2) in the delamination process. This aids the separation of critical elements like silver, copper, etc. from the silicon base.

Read Also: Floating Photovoltaics Mapping: A Future to the Global Solar Development

Supercritical CO2 depicts a state of carbon dioxide wherein its properties overlap between a liquid and gas phase. It is achieved when CO2 surpasses the temperature known as its critical point at high pressure. Under these conditions, the polymers coating the solar cells also experience changes in their properties. At 31°C under 73.8 bars of pressure, CO2 infringes on the solid state. Upon depressurization, the CO2 within the coating turns back into its gaseous state, resulting in the expansion and foaming of the polymer.

The subsequent deformation provides adequate conditions necessary for the separation of the layers present in the PV cell, enabling individual recovery. With more than 30% of the panel value attributed to its silver composition and a majority of its weight contributed by silicon, a guarantee of maximum purity is of the essence for the success of the process.

In conclusion, CEA’s solar panels recycling strategy stands to be highly beneficial to the development and maintenance of the solar power sector of the green energy industry. It has partly solved a potential issue that society never considered. Presently focusing on retrieving only two elements, the innovation has yet to live up to its full potential.

Joshua Austin joined News Gazzte as a senior editor in 2023. Joshua is an automotive journalist who previously worked as an autonomous vehicle test engineer at Uber. He holds a bachelor’s degree in computer science, with a specialization in technical writing and journalism. Joshua’s enthusiasm lies in automotive technology and the evolution of transportation. He remains vigilant in tracking the most recent developments in electric vehicles, autonomous driving, and other emerging technologies.