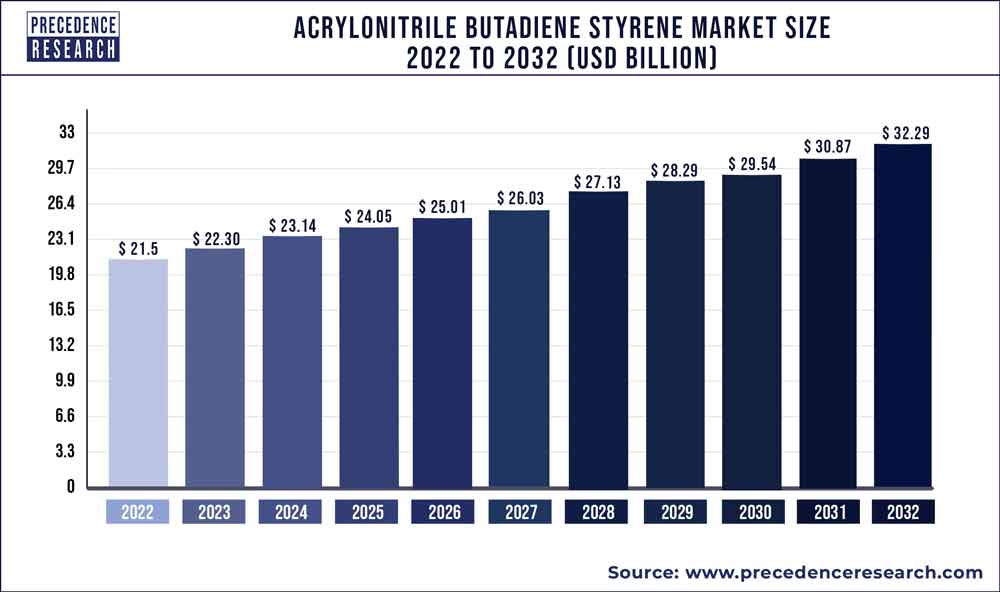

Acrylonitrile Butadiene Styrene Market To Hit USD 32.29 Bn By 2032

The acrylonitrile butadiene styrene market which was USD 22.30 billion in 2023, would rocket up to USD 32.29 billion by 2032 and is expected to undergo a CAGR of 4.20% between 2023 to 2032.

Key Takeaways

- Asia Pacific contributed more than 33% of revenue share in 2022.

- North America is estimated to expand the fastest CAGR between 2023 and 2032.

- By type, the opaque segment has held the largest market share of 40% in 2022.

- By type, the transparent segment is anticipated to grow at a remarkable CAGR of 4.8% between 2023 and 2032.

- By application, the appliances segment generated over 25% of revenue share in 2022.

- By application, the automotive segment is expected to expand at the fastest CAGR over the projected period.

The Acrylonitrile Butadiene Styrene (ABS) market is a dynamic sector within the polymer industry, characterized by the widespread application of ABS copolymers in various manufacturing processes. ABS, a thermoplastic polymer, is renowned for its exceptional strength, impact resistance, and versatile molding capabilities. The market’s growth is propelled by the increasing demand across diverse industries, including automotive, electronics, and consumer goods, where ABS finds extensive utility in manufacturing a wide range of products.

Driver:

A primary driver fueling the growth of the Acrylonitrile Butadiene Styrene market is the burgeoning demand for lightweight and durable materials in manufacturing. As industries worldwide strive for innovative solutions to enhance product performance and efficiency, ABS emerges as a key player. Its unique combination of toughness and ease of processing makes it a preferred choice in the production of automotive components, electronic gadgets, and household appliances. The drive towards sustainability also contributes to the market’s ascent, as ABS can be recycled, aligning with the global push for eco-friendly materials.

Dynamics:

The dynamics of the ABS market are shaped by technological advancements, evolving consumer preferences, and regulatory changes. Ongoing research and development efforts focus on enhancing ABS formulations to meet specific industry needs, fostering a competitive landscape. Market players engage in strategic collaborations and acquisitions to strengthen their presence and broaden their product portfolios. Additionally, the market is sensitive to economic fluctuations and geopolitical factors, influencing raw material prices and supply chain dynamics. As consumer awareness regarding environmental impact grows, the industry responds by exploring bio-based alternatives and sustainable production methods, adding a layer of complexity to the market dynamics.

Get a Sample: https://www.precedenceresearch.com/sample/3560

Acrylonitrile Butadiene Styrene Market Scope

| Report Coverage | Details |

| Market Size in 2023 | USD 22.30 Billion |

| Market Size by 2032 | USD 32.29 Billion |

| Growth Rate from 2023 to 2032 | CAGR of 4.20% |

| Largest Market | Asia Pacific |

| Base Year | 2022 |

| Forecast Period | 2023 to 2032 |

| Segments Covered | By Type and By Application |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Type:

General Purpose ABS: General purpose ABS is the most common type and is widely used across various industries. It possesses a balanced combination of toughness and rigidity, making it suitable for a broad range of applications. Common uses include automotive components, consumer goods, and construction materials.

High Impact ABS: High-impact ABS is specifically formulated to exhibit enhanced impact resistance. This type of ABS is often preferred in applications where the material may undergo stress or impact, such as in the production of protective gear, toys, and electronic enclosures.

Flame Retardant ABS: Flame retardant ABS is engineered to meet stringent fire safety standards. This type finds applications in electronics and electrical components, where fire resistance is a critical requirement.

Weatherable ABS: Weatherable ABS is designed to withstand exposure to outdoor elements, making it suitable for applications such as outdoor furniture, automotive exterior parts, and construction materials.

Application:

Automotive: ABS is extensively used in the automotive industry for various applications, including interior and exterior components. This encompasses the manufacturing of dashboards, bumpers, trim parts, and other structural elements due to its combination of strength, impact resistance, and aesthetic appeal.

Consumer Goods: ABS is a popular choice in the production of consumer goods. Items such as toys, luggage, appliances, and sporting equipment benefit from ABS’s durability, lightweight nature, and the ability to be molded into intricate shapes.

Electronics and Electrical: ABS is a preferred material for electronic enclosures and housings due to its electrical insulation properties. It is utilized in the production of items like computer peripherals, electrical connectors, and other electronic components.

Construction and Pipe Fittings: ABS’s durability, chemical resistance, and ease of installation make it suitable for construction applications. It is commonly used in the production of pipes and fittings for plumbing and drainage systems.

Others: ABS finds applications in various other industries, including healthcare, where it may be used in medical devices, and in the production of industrial components requiring a balance of strength and moldability.

Read Also: Acrylate Market will be Worth Nearly $ 19.96 Billion By 2032

Recent Developments

- In June 2021, Nexeo Plastics and Covestro jointly introduced the Polycarbonate/ABS 3D printing filament, Addigy FPB 2684 3D, available through Nexeo Plastics’ distribution platform. This launch signifies a strategic move to expand their 3D printing product range, showcasing a commitment to investing in innovative solutions.

- In January 2021, INEOS Styrolution initiated the “LIFE ABSolutely Circular” project, constructing a demonstration plant in Antwerp, Belgium, to test the production of ABS plastic from recycled feedstock. This effort underscores a commitment to exploring advanced recycling technologies, aiming to demonstrate both environmental and economic advantages in closing the loop of plastic recycling.

Acrylonitrile Butadiene Styrene Market Players

- LG Chem

- INEOS Styrolution

- SABIC

- BASF SE

- Covestro

- Chi Mei Corporation

- Trinseo

- Formosa Chemicals & Fibre Corp.

- Asahi Kasei Corporation

- Toray Industries, Inc.

- Kumho Petrochemical Co., Ltd.

- Teijin Limited

- LOTTE Chemical CORPORATION

- Ravago

- Mitsubishi Chemical Corporation

Segments Covered in the Report

By Type

- Opaque

- Transparent

- Colored

By Application

- Appliances

- Electrical and Electronics

- Automotive

- Consumer Goods

- Construction

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Contact Us:

Mr. Alex

Sales Manager

Call: +1 9197 992 333

Email: sales@precedenceresearch.com

Web: https://www.precedenceresearch.com

Blog: https://www.expresswebwire.com/

Blog: https://www.uswebwire.com/

Blog: https://www.dailytechbulletin.com/