Knitting Machine Market Size to Gain USD 10.54 Bn by 2034

Knitting Machine Market Size and Forecast 2025 to 2034

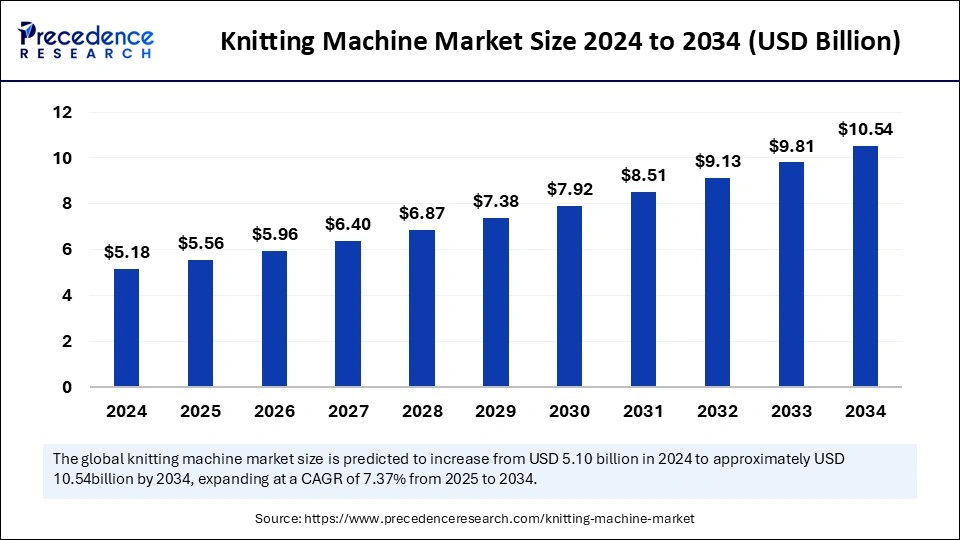

The global knitting machine market size was valued at USD 5.18 billion in 2024 and is expected to gain around USD 10.54 billion by 2034, growing at a CAGR of 7.37%.

Knitting Machine Market Key Points

-

Asia Pacific held the highest market share in 2024 (41%).

-

North America is expected to be the fastest-growing regional market.

-

The weft-knitting machine system was the most widely used type.

-

Warp-knitting machines are projected for significant future expansion.

-

Double-knit was the preferred knit type in 2024.

-

Single knit fabrics are on a rapid growth trajectory.

-

Fully automatic operation dominated in 2024.

-

Semi-automatic machines are expected to gain traction.

-

Apparel textiles saw the highest demand by end-use.

-

Sports textiles are likely to be a future growth driver.

-

Direct sales topped distribution methods in 2024.

-

Indirect sales channels will grow fastest through 2034.

Role of AI in the Knitting Machine Market

Artificial Intelligence (AI) is revolutionizing the knitting machine market by enabling smart automation, real-time quality control, and predictive maintenance. AI-powered knitting machines can automatically adjust stitch density, fabric tension, and patterns with high precision, reducing human intervention and material waste. Sensors and data analytics allow for predictive maintenance, minimizing downtime and enhancing machine lifespan, while also ensuring consistent product quality by instantly detecting defects.

Additionally, AI supports customization and innovation in design by analyzing consumer trends and past production data. This allows manufacturers to create personalized patterns, switch between fabric types with ease, and respond faster to market demands. AI also improves energy efficiency and simplifies machine operation, making knitting processes more sustainable and user-friendly across fashion, sportswear, and industrial textile sectors.

Knitting Machine Market Growth Factors

-

Rising Demand for Apparel & Fashion Wear

The growing global population, fast fashion trends, and increased consumer spending on clothing are boosting the demand for high-volume textile production, propelling the adoption of advanced knitting machines. -

Technological Advancements

Innovations such as computer-controlled knitting systems, AI integration, and automation are enhancing precision, speed, and customization capabilities, making knitting machines more efficient and appealing to manufacturers. -

Growth of the Sportswear and Activewear Segment

The rising health and fitness awareness has fueled demand for functional and comfortable sports textiles, leading to higher demand for machines that can produce stretchable, breathable, and durable fabrics. -

Increasing Textile Manufacturing in Emerging Economies

Countries like China, India, Bangladesh, and Vietnam are investing heavily in textile manufacturing infrastructure, creating substantial opportunities for knitting machine vendors. -

Customization and Mass Personalization

The ability of modern knitting machines to produce intricate and personalized designs is attracting manufacturers aiming to meet diverse consumer preferences and market niches. -

Sustainable and Eco-Friendly Production Trends

Knitting machines are increasingly being used in sustainable textile production due to their low waste output and energy-efficient operations, aligning with the industry’s push toward eco-conscious manufacturing.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 10.54 Billion |

| Market Size in 2025 | USD 5.56 Billion |

| Market Size in 2024 | USD 5.18 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 7.37% |

| Dominated Region | Asia Pacific |

| Fastest Growing Market | North America |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Type, Knit Type, End Use, Mode Of Operation, Distribution Channel, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Key Market Drivers

-

Technological Advancements

The incorporation of advanced technologies like automation, computerized systems, and smart technologies in knitting machines is improving efficiency and enhancing production capabilities. These innovations help textile manufacturers produce high-quality, customized products at faster speeds. -

Rising Demand for Customized and High-Quality Apparel

Consumers are increasingly looking for high-quality, personalized clothing options, prompting the knitting machines market to innovate for higher levels of customization and intricate designs. This trend is especially prominent in sectors like sportswear, luxury fashion, and athleisure, where the demand for unique and detailed apparel is growing rapidly. -

Sustainability Initiatives

The growing trend of sustainable fashion is encouraging the adoption of energy-efficient and eco-friendly knitting solutions, further expanding the market.

Emerging Opportunities

-

Expanding Applications of Knitted Fabrics

The versatility and adaptability of knitted fabrics make them suitable for a wide range of applications, from high-performance sportswear to comfortable and breathable garments. The growing demand for technical textiles, such as antimicrobial and moisture-wicking fabrics, is further expanding the application areas of knitted fabrics. -

Integration of Smart Technologies

The integration of smart technologies, such as artificial intelligence (AI), automation, and data-driven analytics, is making knitting machines more efficient, flexible, and capable of producing more intricate designs and customized products. By using automated systems, manufacturers can optimize production, reduce human error, and improve overall operational efficiency.

Market Challenges

-

High Initial Investment

One of the primary challenges facing the knitting machines market is the high cost associated with advanced technologies, particularly for small and medium-sized manufacturers. While innovations such as computerized, automated, and smart knitting machines have revolutionized the industry by improving production efficiency, reducing labor costs, and enabling the creation of more complex designs, the initial investment required for these machines is substantial. -

Intense Competition and Rapid Technological Changes

The knitting machine market faces challenges such as intense competition, rapid technological advancements leading to product obsolescence, and fluctuations in raw material prices. Additionally, the industry is impacted by factors such as geopolitical uncertainties and economic downturns.

Regional Insights

-

Asia-Pacific

Asia Pacific is expected to hold a dominant share of the knitting machines market due to the strong presence of textile manufacturing hubs in countries like China, India, and Bangladesh. The high demand for knitted garments, along with the availability of skilled labor and cost-effective manufacturing processes, is driving the market growth in this region. -

Europe and North America

Europe and North America are also contributing to market expansion, driven by the demand for high-quality knitting machines in apparel and technical textiles, as well as the integration of advanced technologies. -

Latin America and Middle East & Africa

In Latin America and the Middle East & Africa, there is an increasing adoption of modern knitting machines to enhance production capabilities and meet the growing demand for textiles, further supporting global market growth.

Knitting Machine Market Companies

- Flying Tiger

- Fukuhara

- Hanma group

- Jingwei Textile Machinery

- Lamb

- Lisky

- Mayer and CIE

- Orizio

- Pai Lung

- Santoni

- Shima Seiki

- Stoll

- Tompkins

- Yamato Sewing Machine

- Zentex

Leaders Announcement

- In February 2025, TotalEnergies and Mayer and Cie announced a partnership to co-brand the Tixo Stainless knitting machine oil range. Signed on February 6, 2025, the agreement combines TotalEnergies’ high-performance lubricants with Mayer and Cie’s advanced knitting machines to enhance efficiency and durability in textile production.

Recent Developments

- In January 2025, seamless knitting machine specialist Santoni partnered with UK-based Vickers to develop a needle lubricant solution for its flagship large-diameter knitting technology, enhancing performance and efficiency.

In November 2024, A.T.E., a leading Indian textile engineering company, and UNITEX Singapore announced a partnership to promote knitting machines in India. This collaboration leverages their combined expertise to expand the adoption of advanced knitting technology in the Indian textile sector.

Segments Covered in the Report

By Type

- Warp knitting machines

- Raschel warp

- Tricot warp

- Others (crochet, etc.)

- Weft knitting machines

- Circular

- Straight bar

- Others (loop wheel, etc.)

By Knit Type

- Single knit

- Double knit

By Mode of Operation

- Manual

- Semi-automatic

- Fully automatic

By End Use

- Automotive textiles

- Sports textiles

- Apparel textiles

- Home textiles

- Others (footwear industry, etc.)

By Distribution Channel

- Direct sales

- Indirect sales

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Also Read: Embroidery Machine Market

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/