Test Benches Market Size to Achieve USD 2.56 Bn by 2034

Test Benches Market Size and Forecast 2025 to 2034

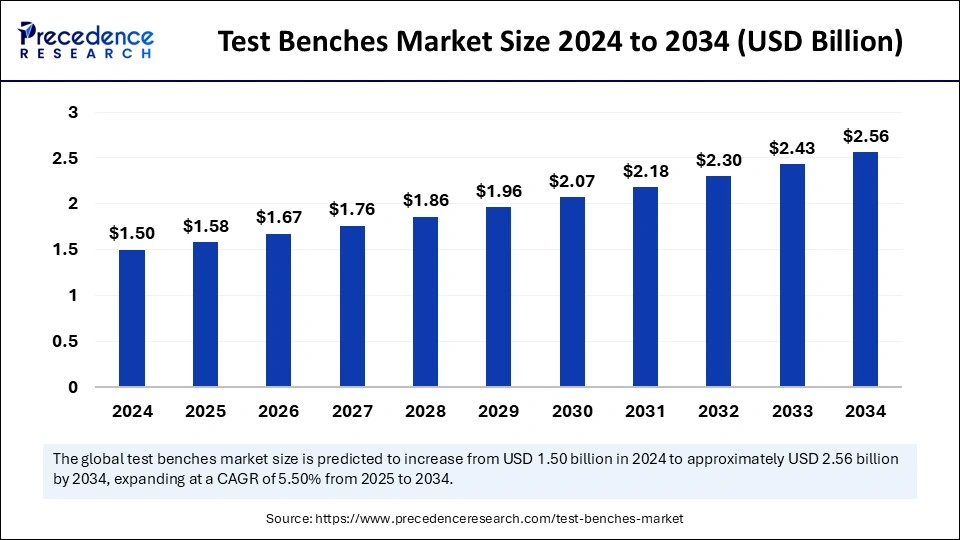

The global test benches market size was valued at USD 1.50 billion in 2024 and is expected to achieve around USD 2.56 billion by 2034, growing at a CAGR of 5.50% from 2025 to 2034.

Get a Free Sample Copy of the Report@https://www.precedenceresearch.com/sample/5796

Test Benches Market Key Insights

Regional Insights:

-

North America led with a 35% market share in 2024.

-

Asia Pacific is on track to grow at the fastest pace in the coming years.

By Component:

-

Hardware dominated the segment with 54% market share.

-

Software is forecasted to grow rapidly due to digital transformation.

By Type:

-

Valve test benches were the most in-demand in 2024.

-

Torque test benches are expected to experience notable growth.

By Test Stands:

-

Motorized test stands held the top spot in 2024.

-

Manual test stands are expected to outpace in growth.

By Test Material:

-

Valve testing was the top material application.

-

Furniture testing is emerging as a high-growth segment.

By Application:

-

Automotive and transportation was the dominant application area in 2024.

-

Oil and gas is projected to expand at the highest CAGR during the forecast period.

Role of AI in Test Benches Market

Artificial Intelligence (AI) is significantly transforming the test benches market by enhancing accuracy, efficiency, and automation across various testing processes. AI-powered systems enable real-time data collection and advanced analytics, allowing for predictive maintenance, fault detection, and performance optimization. These smart test benches can learn from previous test cycles to improve future testing procedures, reducing downtime and enhancing productivity.

In sectors like automotive, aerospace, and electronics, AI-integrated test benches help simulate complex environments, ensuring that components meet rigorous quality standards. Machine learning algorithms can analyze test data to identify patterns, detect anomalies, and provide actionable insights without human intervention. Additionally, AI improves user interface design, enabling more intuitive control systems and diagnostics.

What Are Test Benches?

Test benches are specialized equipment or systems used to test the functionality, performance, and durability of various components, assemblies, or systems in a controlled environment. They are widely used across industries such as automotive, aerospace, electronics, manufacturing, oil & gas, and power generation to ensure that parts meet safety, efficiency, and quality standards before deployment.

These setups simulate real-world operating conditions to evaluate how a product behaves under different stress levels, load capacities, environmental changes, and operational scenarios. Depending on their design and purpose, test benches can be manual, semi-automated, or fully automated.

Types of Test Benches:

-

Valve Test Benches: Used to assess valve performance under different pressure and flow conditions.

-

Torque Test Benches: Measure torque output and durability, especially in engines and motors.

-

Motorized Test Stands: Provide automated, repeatable testing for precise results.

-

Manual Test Stands: Offer more control and flexibility for small-scale or custom tests.

Applications:

-

Automotive: Testing engines, transmissions, brakes, and electric motors.

-

Aerospace: Verifying avionics and mechanical systems under flight-like conditions.

-

Electronics: Functional testing of PCBs, circuits, and electronic devices.

-

Industrial Manufacturing: Checking the reliability of machines, tools, and mechanical parts.

Why They Matter:

Test benches help prevent product failures, reduce recalls, and ensure compliance with industry regulations. They are essential for R&D, quality assurance, and product validation, giving manufacturers confidence in their final output.

Test Benches Market Growth Factors

1. Rising Demand for Quality Assurance in Manufacturing

As industries place greater emphasis on product reliability and performance, the need for rigorous testing solutions is rising. Test benches enable real-time simulation and validation, ensuring components meet safety and durability standards. This is especially vital in sectors like automotive, aerospace, and industrial machinery.

2. Expansion of the Automotive and EV Sector

The automotive industry, particularly the electric vehicle (EV) segment, relies heavily on test benches to assess engines, motors, batteries, and other components. The increasing adoption of EVs has created a surge in demand for advanced test benches designed to handle new propulsion technologies.

3. Technological Advancements in Testing Equipment

Innovations such as IoT-enabled test benches, AI-integrated diagnostics, and real-time monitoring systems have made test benches smarter and more efficient. These enhancements improve precision, reduce downtime, and provide valuable data analytics for predictive maintenance and R&D.

4. Increased Focus on Safety and Compliance

Stricter industry regulations and safety standards across sectors like aerospace, oil & gas, and defense are pushing companies to invest in high-quality test equipment. Test benches help organizations comply with certifications and avoid costly product failures or legal liabilities.

5. Growing Industrial Automation

The broader trend of industrial automation and Industry 4.0 integration is leading to more automated and software-driven testing systems. Test benches are evolving to support automated production lines and remote diagnostics, boosting their adoption in smart factories.

6. Global Infrastructure and Energy Projects

Ongoing development in power generation, infrastructure, and energy systems requires the testing of valves, pumps, turbines, and other mechanical equipment—driving demand for specialized test benches in these applications.

Market Scope

| Report Coverage | Details |

| Market Size by 2034 | USD 2.56 Billion |

| Market Size in 2025 | USD 1.58 Billion |

| Market Size in 2024 | USD 1.50 Billion |

| Market Growth Rate from 2025 to 2034 | CAGR of 5.50% |

| Dominated Region | North America |

| Fastest Growing Market | Asia Pacific |

| Base Year | 2024 |

| Forecast Period | 2025 to 2034 |

| Segments Covered | Component, Type, Test Stands, Test Material, Application, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Market Dynamics

Market Drivers

One of the key drivers propelling the test benches market is the increased demand for quality assurance and safety regulations across industries. Automotive manufacturers, especially with the rise of electric vehicles, are using test benches extensively to assess engines, batteries, transmissions, and braking systems.

The push for automation and Industry 4.0 is another significant factor, with industries integrating smart and IoT-enabled testing solutions to improve operational efficiency. Additionally, advancements in material testing and the need for validation of high-performance machinery in aerospace and defense further bolster market growth.

Market Opportunities

The test benches market holds substantial opportunities, particularly through the integration of artificial intelligence, machine learning, and real-time data analytics. These technologies can enhance predictive maintenance, optimize testing processes, and minimize downtime. The growing trend of digital twins and remote diagnostics also opens new pathways for innovation in test bench design.

Moreover, emerging markets in Asia Pacific and Latin America are experiencing rapid industrialization, creating a fertile environment for the expansion of advanced testing infrastructure. There’s also a growing opportunity in renewable energy and electric grid systems, where components need rigorous validation.

Market Challenges

Despite promising growth, the market faces several challenges. High initial costs of advanced test benches, especially those with automation and software integrations, can be a barrier for small and medium enterprises. Maintenance requirements and calibration complexities also add to the operational burden.

Additionally, the lack of skilled technicians to operate and interpret results from sophisticated testing systems may limit broader adoption. In some sectors, resistance to shifting from traditional testing methods to automated solutions can also slow market penetration.

Regional Insights

North America currently leads the global test benches market, driven by strong demand from the automotive, aerospace, and defense sectors. The region benefits from well-established manufacturing infrastructure and a strong focus on innovation. Asia Pacific is projected to grow at the fastest pace due to rapid industrial expansion, increasing investment in automation, and the booming electric vehicle market in countries like China and India.

Europe holds a significant market share, supported by stringent regulatory standards and a well-developed industrial base, especially in Germany, the UK, and France. Meanwhile, Latin America and the Middle East & Africa are gradually emerging as potential markets due to growing investments in infrastructure and energy sectors.

Test Benches Market Companies

- Com-Ten Industries

- EFCO Maschinenbau GmbH

- ABL Automazione S.r.l.

- AMETEK.Inc.

- ANDILOG Technologies

- ATEQ Corp.

- Blum-Novotest GmbH

- Bosch Rexroth AG

- Keysight Technologies

- NATIONAL INSTRUMENTS CORP.

- Moog Inc.

- Rohde & Schwarz

- Kistler Group

Latest Announcements by Market Leaders

- In November 2024, Virtek Vision International Inc. announced that it had been acquired by AMETEK, Inc., as part of its Electronic Instruments Group (EIG) – a leader in advanced analytical, monitoring, testing, calibrating, and display instrumentation. Virtek will continue to operate as an independent organization through AMETEK’s Creaform business.

- In October 2024, WTR Andretti Racing Team, a motorsports team competing in the IMSA SportsCar Championship, announced that it would be leveraging the AMETEK Lloyd LD 50 material testing solution for premium suspension testing of its race cars. The team would use the machine to test and calibrate its strain gauges and sensors, enabling it to make the required adjustments to optimize car performance.

Recent Developments

- In October 2024, MBJ Solutions, a German testing equipment specialist, recently launched two new products for developers of perovskite and perovskite silicon tandem devices. The MBJ Steady State Sun Simulator is designed for cells and small perovskite module research, and the MBJ Light Soaking Unit is for aging tests and preconditioning.

- In January 2024, Bosch Rexroth announced a partnership with leading thermal management manufacturer Modine. The two organizations are collaborating to bring Modine EVantage (™) thermal management systems to the Bosch Rexroth portfolio of eLION products for electrified off-highway machinery worldwide.

Segments Covered in the Report

By Component

- Hardware

- Software

By Type

- Valve

- Force

- Torque

- Others

By Test Stands

- Manual

- Motorized

By Test Material

- Valve

- Motors

- Furniture

- Others

By Application

- Semiconductor and Electronics

- Industrial Manufacturing and Engineering

- Automotive and Transportation

- Power Generation and Utilities

- Oil and Gas

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

Also Read: Digital Watch Market

Ready for more? Dive into the full experience on our website@ https://www.precedenceresearch.com/