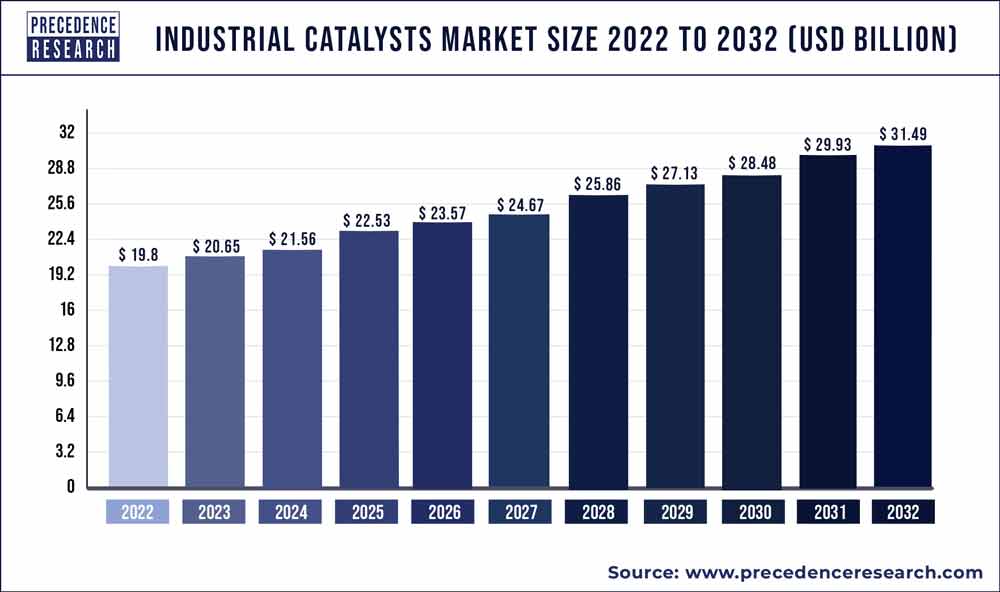

Industrial Catalysts Market Size To Touch USD 31.49 Bn By 2032

The industrial catalysts market size is poised to grow by $ 31.49 billion by 2032 from $ 20.65 billion in 2022, exhibiting a CAGR of 4.80% during the forecast period 2023-2032.

By Type

Industrial catalysts come in various types, each serving a distinct purpose in chemical processes. One prominent category is heterogeneous catalysts, which exist in a different phase from the reactants. These catalysts often involve solid surfaces, enhancing reaction rates and selectivity. Homogeneous catalysts, on the other hand, share the same phase as the reactants, typically in liquid form. This type offers uniform distribution and efficient catalysis in solution-based reactions.

By Material

Diverse materials contribute to the effectiveness of industrial catalysts. Among them, metals such as platinum, palladium, and nickel play crucial roles in catalyzing chemical reactions. These metallic catalysts often exhibit high activity and durability. Additionally, metal oxides, zeolites, and other structured materials find applications, providing specific catalytic properties suitable for various industrial processes. The choice of material depends on the targeted reactions and desired catalytic performance.

By Application

The Industrial Catalysts Market finds extensive applications across diverse industries. In the petrochemical sector, catalysts play a pivotal role in refining processes, facilitating the conversion of crude oil into valuable products like gasoline and diesel. Environmental applications involve catalysts in emission control systems, reducing pollutants in exhaust gases. Furthermore, the chemical industry relies on catalysts for the synthesis of numerous compounds, enhancing reaction efficiency and yield. Each application demands specific catalytic properties, leading to a wide array of catalyst formulations tailored to meet industry-specific needs.

Read Also: Healthcare Predictive Analytics Market Size To Rise USD 98.54 Billion By 2032